The Elementor floor hatch is the most basic hidden floor hatch from the VHID floor hatches range. It has a simple removable Nexus hidden black steel hinge and opens with shock absorbers. It is suitable for creating an invisible entrance of small sizes in basements, cellars, on the basement floors, in technical rooms of mostly private houses. It is also possible to use Elementor outdoors, but under a covering and under the condition of limiting constant contact with water.

Elementor floor hatch is designed for cladding with materials of medium weight, such as laminate, linoleum, ceramic and vinyl tiles, ceramic granite up to 12 mm thick or other materials of similar weight. The maximum thickness of the facing material together with the glue that can be applied to the floor hatch is 15 mm. If the facing material is thicker, it is possible to order an individual design with changes in the hinge.

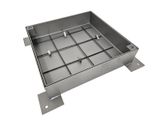

The structure of the floor hatch consists of a steel corner frame and a lid connected by the Nexus axial hinge. The rotating mechanism of the Nexus hinge is hidden in the floor hatch frame, and the lid is attached to it with the help of P-shaped plates, which allows it to be opened by 90 degrees. The hinge takes up minimal free space in the floor hatch. Opening is semi-automatic and is provided by gas springs.

The outside dimensions of a steel corner frame are 40 x 40 x 3 mm. The body of the lid is made of 25 x 40 x 2 mm steel profiles and stiffeners (20 x 40 x 1.2 mm steel profile). The sides of the body of the lid are connected by stiffeners to strengthen and protect it from deformation under heavy loads. From above, the lid is covered with KNAUF drywall (GVL) 10 mm thick. A rubber seal is placed between the surface of the lid and the corner, which is attached around the perimeter of the lid. The depth of the floor hatch structure in the closed state is 40 mm, near the P-shaped protrusion of similar hinge plates - 90 mm, near shock absorber holders - 115 mm.

Profiles for hidden floor hatches in the Elementor hatch are used exclusively from electrowelded carbon cold-rolled black steel, which undergoes phosphate treatment and is covered with polyester powder paint, which ensures its anti-corrosion. Welds are made by the MIG method according to the international standard DIN EN ISO 5817.

The floor hatch lid opens semi-automatically perpendicular to the floor at 90° using industrial gas shock absorbers fixed on special holders. In addition, the floor hatch is equipped with a rotary latch lock, which can be opened with a special key both from the outside and from the inside. The lock closes automatically when the floor hatch is closed. In most cases, when the lock is opened, the floor hatch opens without additional effort, but if the floor hatch cover is heavy and the floor hatch does not open on its own, you need to use a lifting handle, for which an additional hole on the lid and a decorative plug are provided.

To open the floor hatch:

The number of gas shock absorbers to be installed on the floor hatch is determined at the factory, based on the information about the load level, material, weight, area of the floor hatch cover and the side of the hinges. For the floor hatch, springs are used without a damper (tensioner) and without the possibility of adjusting the gas pressure in them.

The minimum possible size of the structure with one lid is 600 L x 600 W (W is the side of the hinge) mm, the maximum is 1000 L x 1200 W (W is the side of the hinge) mm. A design with two lids is not provided. If you need the floor hatch of larger outside dimensions, the MARAUS model is recommended.

Elementor floor hatch is designed for a maximum load of 400 kg/1 square m, so you can walk freely on it.

Important! A load greater than the recommended one can cause deformation of the floor hatch frame, and the lid will not open! Any car collision will also cause deformation.

The recommended outside dimensions of the floor hatch should be 10 mm smaller than the opening in the ceiling between the premises to leave an installation gap.

If you need to calculate the overall size of the floor hatch for the size of the tile, you need to measure the dimensions of the tile that will be placed on the lid, taking into account the thickness of the seams between the tile fragments. The width L (perpendicular side of the hinge) of 51 mm should be added to the measured dimensions of tiles with seams. 12 mm should be added along the length W (side of the hinge). If this condition is met, the gap between the tile on the lid and the tile on the floor will be equal to 2 mm. If you need seams of a different width, you must accordingly reduce or increase the overall size of the floor hatch when ordering.

If you met these conditions, the tile should be placed on the lid so that it protrudes beyond its limits by 2 mm on three sides of the floor hatch, except for the side where the hinge will be placed. On the side of the hinge, the tile should protrude by 7 mm!

Important!!! The clear/useful opening of the floor hatch along the width L (perpendicular side of the hinge) is less by 90 mm (near the hinge protrusion - 130 mm), along the length W (side of the hinge) - by 80 mm (including the frame).

Important!!! Installation of floor hatches is possible only in a horizontal position;

Important!!! In the standard configuration, floor hatches contain fastening elements and openings in them;

Important!!! It is forbidden to operate the floor hatch with connected gas springs until the work on laying the floor covering is finished!

Before starting the work, it is necessary to remove the gas springs from the floor hatch (if they were installed). The manufacturer always supplies products with the gas springs removed. The gas springs are packaged separately from the other elements of the floor hatch and placed in the rear of the floor hatch.

1. Preparation of the opening

Prepare the opening of the correct geometric shape (rectangular or square) with 90° corners in the concrete or wooden floor. The overlap thickness between floors should be at least 200 mm. If the overlap is less than 200 mm, you need to provide additional fasteners for fixing the floor hatch. Do not start laying the finishing lining before installing the floor hatch!

2. Fixing the floor hatch in the opening

Elementor floor hatch is installed exclusively in the middle of the opening in the concrete or wooden floor.

Calculate the level to which the floor hatch mounting plates will be lowered in the opening so that the top of the lid is in one plane with the rough floor. This will be an assembly line. Mark it on the walls of the opening. Lower the floor hatch into the opening to the level of the assembly line and screw the mounting plates to the walls of the opening using mounting anchors.

Make sure that the floor hatch is installed without distortion of the frame and in one plane with the surface of the wall or ceiling.

Fill the gaps between the concrete floor and the lid frame with cement or another fixative and sealing solution.

3. Facing

After installing the floor hatch in the mounting opening, apply the facing material. Make holes in the facing material for the key and, if necessary, also for the lifting handle.

Apply a layer of tile adhesive to the drywall of the lid, following the recommendations for its use.

Stick the facing material on top. The tile should be placed on the lid so that it protrudes beyond its borders by no more than 2 mm on three sides of the floor hatch, except for the side where the hinge will be placed. On the side of the hinge, the tile should protrude 7 mm beyond the lid, and it must be cut at an angle of 60 degrees.

The tile, which is laid from the side of the floor on the steel platform of the hinge, should not reach the gap for the lid by 5 mm. These conditions are calculated for a tile 15 mm thick with glue and for a joint width of 2 mm between the tile on the lid of the hatch and on the floor. As the thickness of the hatch cover decreases, the angle of the undercut must also be reduced so that the hatch opens and the tiles are not damaged.

After finishing laying the facing material, open the floor hatch entrance to 90° and connect the gas springs to the floor hatch with the rod down.

After completion of installation, it is not recommended to walk on the floor hatch for 3 days.

Important!!!

Before closing the floor hatch, it is necessary to check that there are no foreign objects on the frame of the floor hatch, and that the seal is inserted correctly;

Gas springs, and especially the rod, should not be exposed to impact, contamination, or exposure to aggressive environments;

The fastening strength of facing materials should exclude their separation or damage when opening the floor hatch. When operating the floor hatches, water/dirt must be avoided in the floor hatch hinges to avoid jamming or corrosion. In case of deterioration of floor hatch entrance opening properties, it is allowed to lubricate these elements with lubricants.

4. Storage and transportation conditions

Important!!! To achieve the maximum concealment of the floor hatch, the floor covering material should be laid after installing the floor hatch, in the direction from the floor hatch to the walls. It is necessary to calculate the placement of the covering fragments so that the seams are placed along the contour of the floor hatch.

Important!!! Do not leave children unattended when the floor hatch is open, as it is a heavy construction with sharp metallic protrusions, so carelessness in its handling can lead to serious injuries and bodily harm. Be cautious!

Important!!! When closing the floor hatch, make sure that no children, domestic animals, birds or other living creatures are trapped between the frame and the entrance. They can be injured or killed when the floor hatch is being closed.